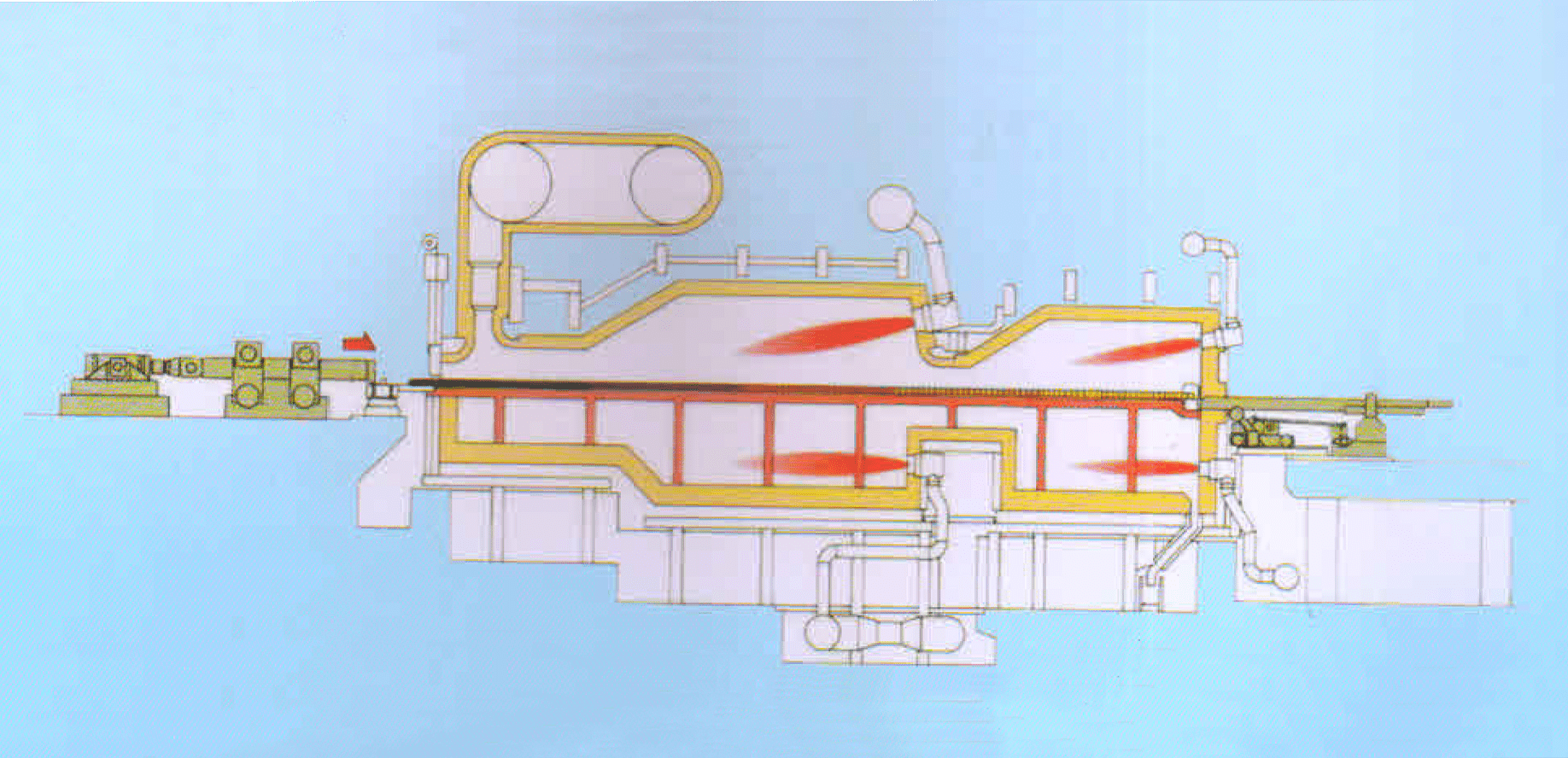

Pusher Type Reheating Furnace

Advantages

Materials are carried by the pusher which is installed at the charging side.

As both the top and the bottom of the materials are heated, the difference in temperature between them hardly occurs.

Because of its simple structure, the maintenance is easy.

Perfect for heating small-size furnaces or small-capacity furnaces.

The experienced manufacturers of furnaces project. Precimax Engineers provide wide range of furnaces in all over the India and in other countries like SAARC, Middle East, Africa and Europe with customize and enhanced technology. We are ranking in top as Pusher Type Reheating Furnace manufacturers, exporters and suppliers in India and overseas with assurance of quality, safety and reliability.

Pusher Type Reheating Furnace Manufacturers

The Pusher type Reheating Furnace is a continuous furnace that allows processing of small, large products. These furnaces are available in electric gas - fired configurations to achieve processing requirements. Pusher furnaces used in machine building or metallurgy to heat metal parts for heat treatment. This type of furnaces can heat parts in high temperature range.

Generally, Pusher Furnaces used for heat treatment for Reheating.

Manufactured by Precimax Engineers, Pusher type Reheating Furnaces are categorized as per design features. We have unique features and our designs have wide flexibility, more reproducibility, low energy costs and customized designs will meet your exact requirements.

- PWHT Furnaces

- Walking Beam Type Reheating Furnace

- Walking Hearth Type Reheating Furnace

- Pusher Type Reheating Furnace

- Post Weld Heat Treatment Furnace

- Solution Heat Treating Furnace

- Aluminum Melting Furnace

- Aluminum Homogenizing Furnace

- Aluminum Coil Annealing Furnace

- Aluminum Slab Reheating Furnace

- Car Type Annealing Furnace

- Regenerative Burner

- Bogie Hearth Furnace

- Pit Furnaces

- Roller Hearth Furnaces