Walking Hearth Type Reheating Furnace

Advantages:

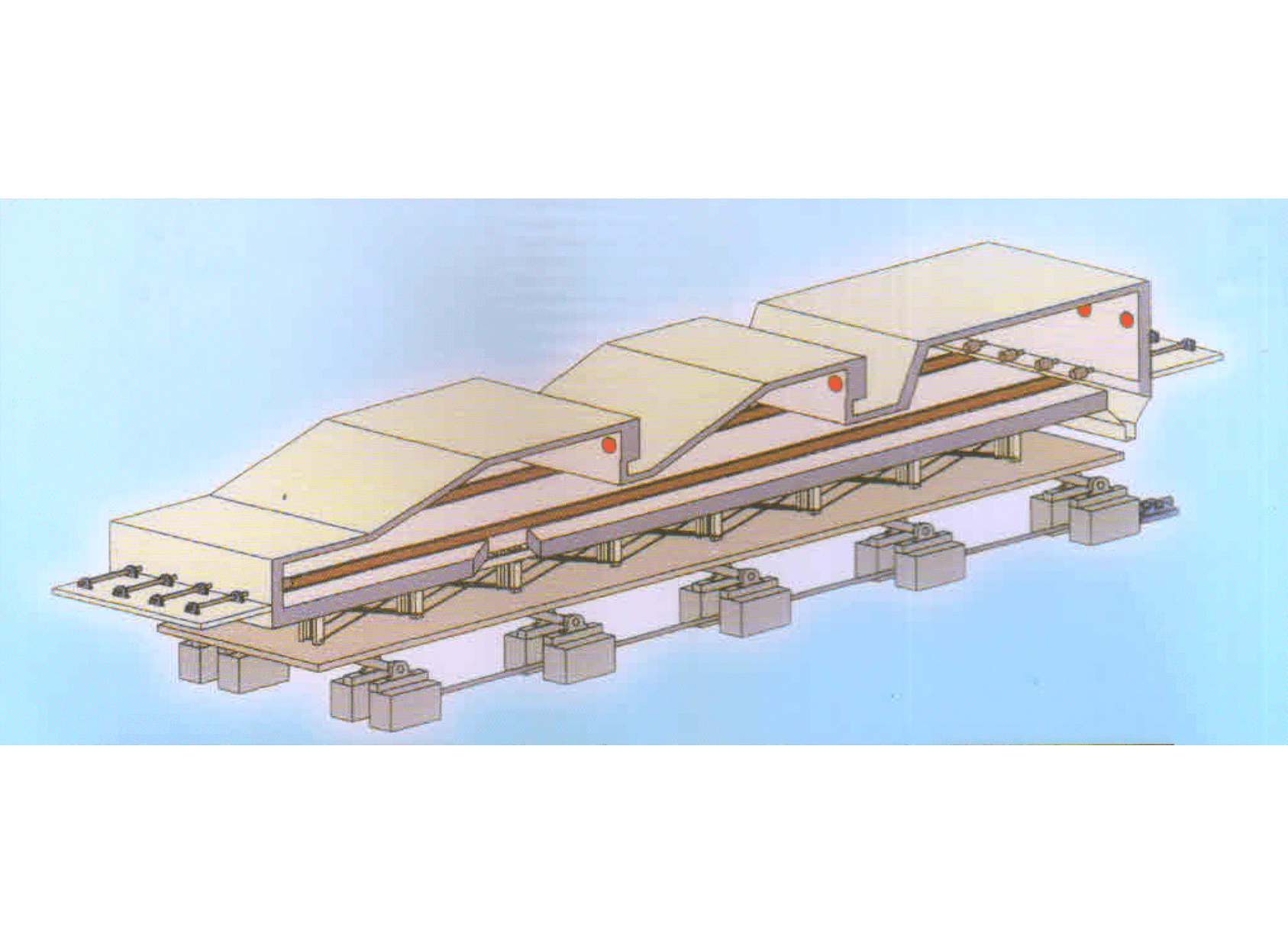

- The walking hearth furnace consists of a stationary hearth and a movable hearth.

- Materials to be heated are carried by the movable hearth which moves rectangularly, i.e. they go up and down, forward and backward.

- Since the movable hearth and the stationary hearth are covered with a refractory material, skid marks are not spotted on materials.

- Since it doesn't use the water cooled beam, it has few water cooling losses.

- Perfect for heating small cross section billets and round billets.

- It's easy to operate.

Walking hearth reheating furnaces consist of stationary hearth and movable hearth. In this furnace materials heated allows the substrate of the furnace to move by lift and shift mechanism. Walking Hearth Furnaces mostly used for alloy steel. We design furnaces that achieve uniform heat distribution.

Walking hearth furnaces have key advantages over pusher furnaces. Such as low decarburization, low scale production, etc. Heating Materials are carried by the movable hearth which moves up and down, forward and backward. The output is not depending on the length of pushing action as well items are not damaged by pushing.

This Furnaces are perfect for heating small cross section billets and round billets. Walking Hearth Type Reheating Furnace are easy to operate.

We are experienced manufacturers of furnaces and export to foreign markets such as Asia, Africa, and Middle East, etc. Walking Hearth Type Reheating Furnace manufacturers, exporters and suppliers to worldwide including India, Middle East & Africa.

- PWHT Furnaces

- Walking Beam Type Reheating Furnace

- Walking Hearth Type Reheating Furnace

- Pusher Type Reheating Furnace

- Post Weld Heat Treatment Furnace

- Solution Heat Treating Furnace

- Aluminum Melting Furnace

- Aluminum Homogenizing Furnace

- Aluminum Coil Annealing Furnace

- Aluminum Slab Reheating Furnace

- Car Type Annealing Furnace

- Regenerative Burner

- Bogie Hearth Furnace

- Pit Furnaces

- Roller Hearth Furnaces